About Water Vapor Transfer (WVT)

Water Vapor Transfer (WVT)

Even though we have identified the problem, concrete moisture continues to be enemy number one in all flooring failures in schools and hospitals as well as commercial offices throughout North America.

Common Failures related to WVT:

- Vinyl Tile – Lifting

- Paint – Blistering and peeling

- Carpeting – Smelly mold

Of course some percentage of failures is due to a dirty or greasy substrates and effloresence and saponification: more on the latter two below.

So moisture is THE problem. Therefore it’s important to find out why the substrate is damp and then block or dry up that moisture. The mosture in both pictured failings is coming directly through the substrate and in both cases it’s concrete.

A few misconceptions that allow this problem to continue:

Misconception 1 – Most people think that water can only go through concrete if there is sufficient hydrostatic pressure (liquid under pressure)

Factually, however, moisture problems are not necessarily caused by hydrostatic pressure. Concrete is hydroscopic: like a sponge it will absorb moisture from the air and if the humidity on one side of the concrete different from the other, it will move moisture to the drier side.

A common mistake about water transfer is the notion that a pool of water, a spring, a river, exists under a slab and the hydrostatic pressure is pushing water through the concrete. Such is rare. Moisture problems can and often do exist in slabs that hang several feet above grade.

Misconception 2 – Moisture problems will not occur if there is a “vapor barrier” between concrete slab and ground or air to stop water in all forms of moisture from entering the concrete. If this were true why do so many concrete slabs and basements with vapor barriers have moisture related problems? Barrier materials are very costly and difficult to put in place. Due to practical field conditions, conventional “vapor barriers” are not effective moisture barriers. There are obvious requirements in almost every slab for column footers as well as electrical, plumbing and other penetrations through the underside of the slab. These penetrations are holes in the barrier and as such violate the “barrier” concept.

Then there are the varmints, critters, rats and mice; animals tear up the plastic and use it for bedding and then the remaining barrier becomes an ideal location for swarms of insects including termites: dark, moist and hidden.

Then there are seem and puncture issues and more. And what about water that is introduced from the dry side and then trapped in the vapor barrier, think plumbing leak. Point is a water vapor barrier/retarder can help but it is not the cure-all.

Water can go through concrete in both its liquid and gaseous form

Liquid Form:

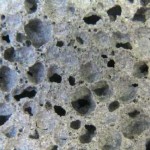

Pores and Capillaries: They are unwanted small tunnels left behind after excess water, not needed chemically, but needed for flowability, has evaporated from the concrete.

Concrete is naturally porous – typically 10 to 18 percent air. To make concrete “workable,” water is added. As concrete cures, the surplus water escapes to its surface where it evaporates, leaving a network of tiny capillaries or pores.

We cannot see the pores, but the average pore is approximately 1 micron, the diameter of a human hair). A water molecule is 3,000 times smaller, so you would expect the water to just pour through the concrete.

So, what holds the water back? Not the concrete but the physics of water itself. It takes pressure to push water through dry microscopic pores. Surface tension holds the “blob” of water inside the dry pore. But add a little water pressure during occasional rainstorms or condensation on the interior and after a while, the pores get wet and the concrete starts leaking. Concrete is hygroscopic – it attracts water by sorption and once wet, the pores draw in groundwater by wicking action (capillary suction).

Gaseous Form or Water Vapor Transfer (WVT)

Water vapor also moves through concrete

As described above there are pores in concrete large enough for liquids to pass, water vapor will use those same pores and more for a passageway.

Vapor pressure will move the vapor through the concrete. Vapor pressure is not hydrostatic pressure.

Vapor Pressure: At each gradient of temperature and humidity, a subtle pressure measured in “pounds per square inch” exists. This pressure has been studied, quantified and has for years been considered in the design of wall systems when moisture vapor movement through a wall is of concern. This same concern must now be recognized in the design of concrete floor slab systems.

When determining a quantifiable rate of moisture flow through concrete the calcium chloride test procedure appears to be the most reliable test available. Manufacturers of most floor coverings feel that vapor emission rates from concrete slabs of greater than 3 pounds/1000 square feet/24 hour period as measured by the calcium chloride method are sufficient to cause flooring problems. They therefore recommend that flooring materials not be installed unless some remedial action to reduce the rate of vapor emission has been accomplished.

A few words about other related moisture problems:

What is effloresence?

Efflorescence is a white crystalline or powdery deposit on the surface of cement-based masonry materials like concrete, brick, clay tile, etc. It’s caused by water seeping through the pores in the cement material. The water dissolves free alkali and lime salts inside the material while migrating through it, and then evaporates leaving the alkali deposited on the surface.

What is saponification?

Saponification is the chemical process of manufacturing soap. When soap is manufactured, the basic ingredients are forms of alkali and oil. The combination of the alkali in the masonry and the oil in the paint causes the saponification, which is the white soapy film which appears on the walls and floors. This also causes flaking, blistering, bleeding and burning off the paint on the surface. Vinyl, rubber or latex based paints also contain some oils and will peel and crack off masonry surfaces.